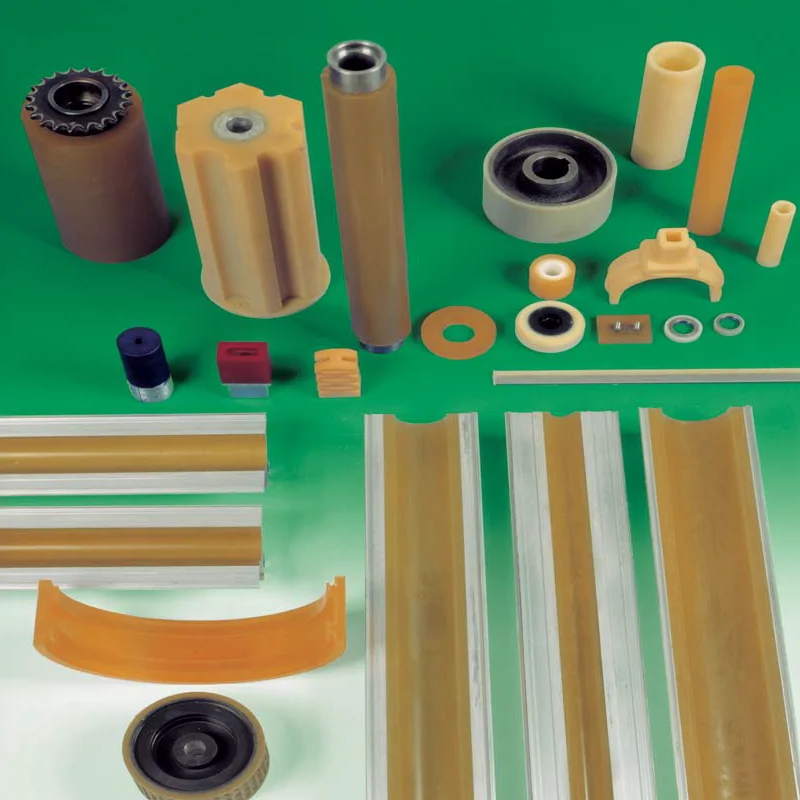

Polyurethane products – for small to medium series

Polyurethane elastomers encompass a wide range of materials processed by casting, compression molding, and injection molding. They all share very high mechanical properties, particularly tensile strength, elongation at break, tear resistance (structural strength), and abrasion resistance.

This allows them to be used even in applications where extreme demands are placed on the material, such as seals in high-pressure hydraulics, rollers and wheels that, due to space constraints, must support heavy loads with a small diameter, pickers and other damping elements, punching pads for automatic cutting systems, fittings, roller covers, and much more.

Numerous specially adapted materials are available for the diverse and diverse applications. A distinction must be made between polyester types (AU) and polyether types (EU).